1. HP MJF Design Guide & Experiments

Company: HP Labs (2017 - 2019)My Role: visual design, 3D modeling, documentation

One of my works at HP Labs was to explore possible 3D-printed designs for HP’s Multi Jet Fusion 3D printers. Combining 2D and 3D design skills and processes, various experimental design examples such as paper-like media, origami, and living hinge structures were created for the explorations. A design guide for the experimental examples was published in the online HP MJF Hand Book distributed on the HP website.

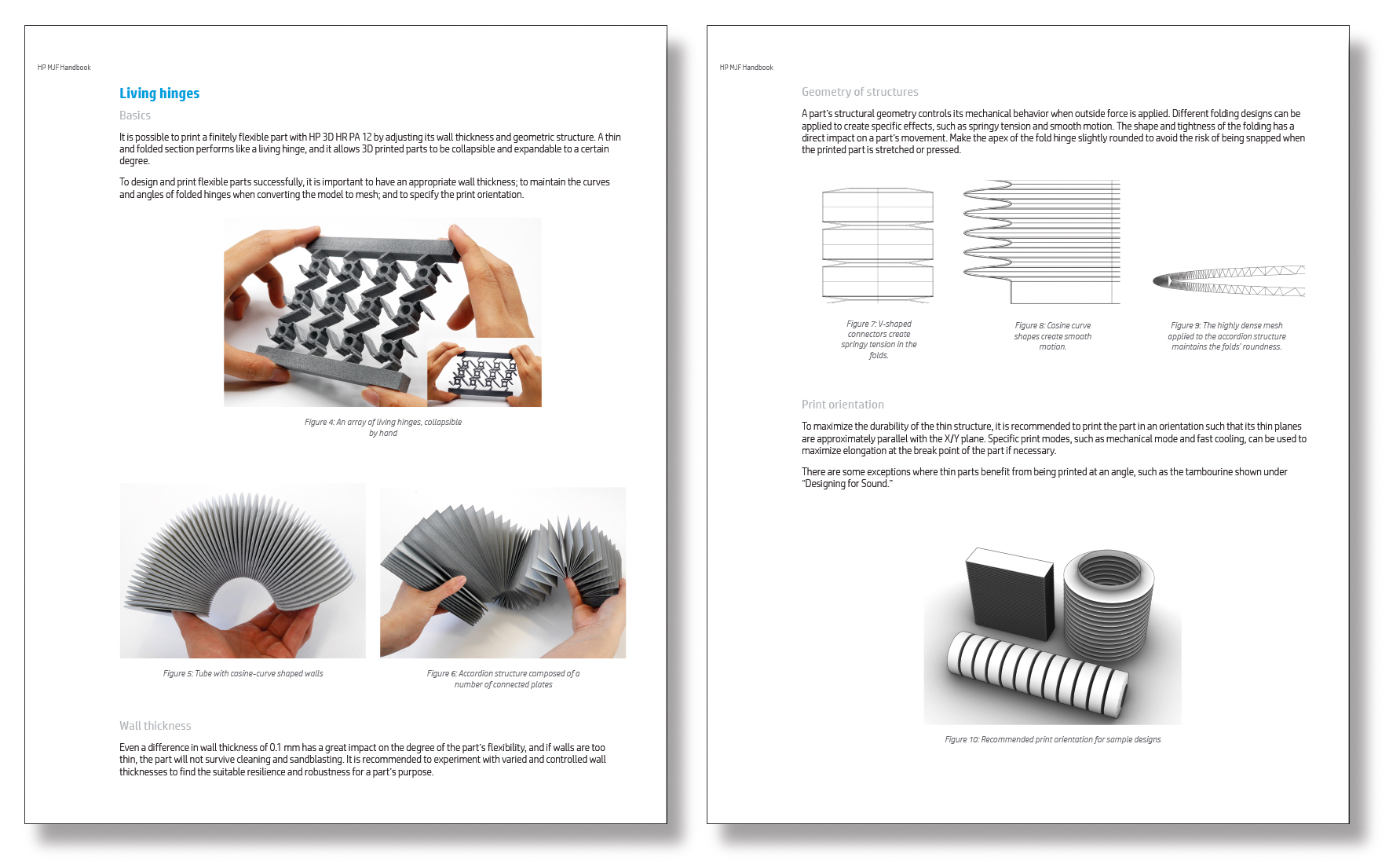

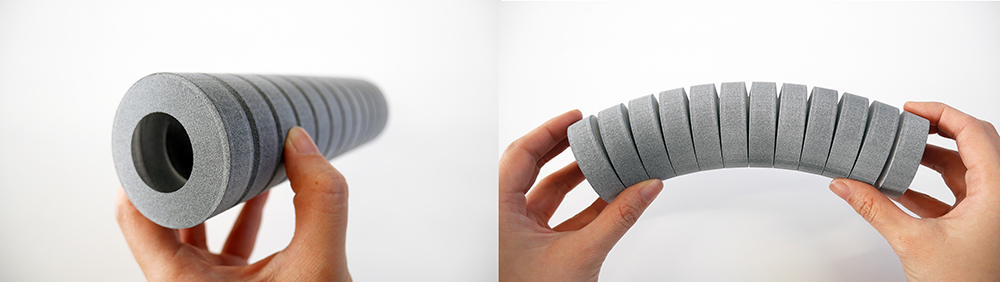

The living hinge design guide for the “Online HP MJF Hand Book”

(you can dowload it from menu > Innovative designs > Hinge design)

(you can dowload it from menu > Innovative designs > Hinge design)

2.5D typography (printed in PA12, dyed black)

Christmas cards with interlocked / moving elements

(printed in PA12, dyed black and purple)

(printed in PA12, dyed black and purple)

Business card & box (printed in PA12, dyed black)

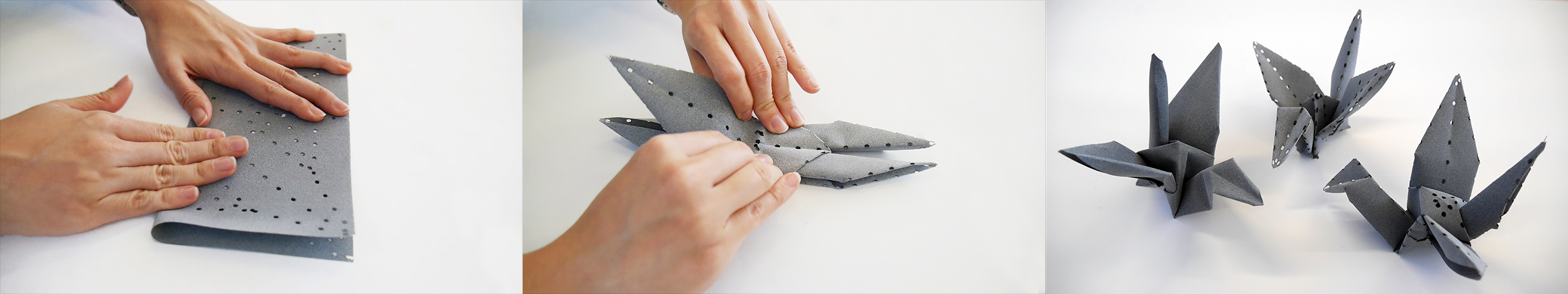

Paper-thin flexible 3D-printed parts (printed in PA12)

Paper-thin flexible 3D-printed parts (printed in PA12)

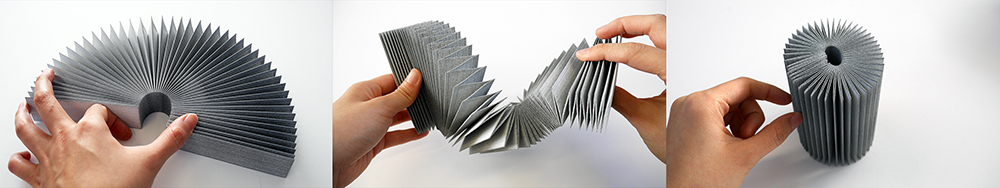

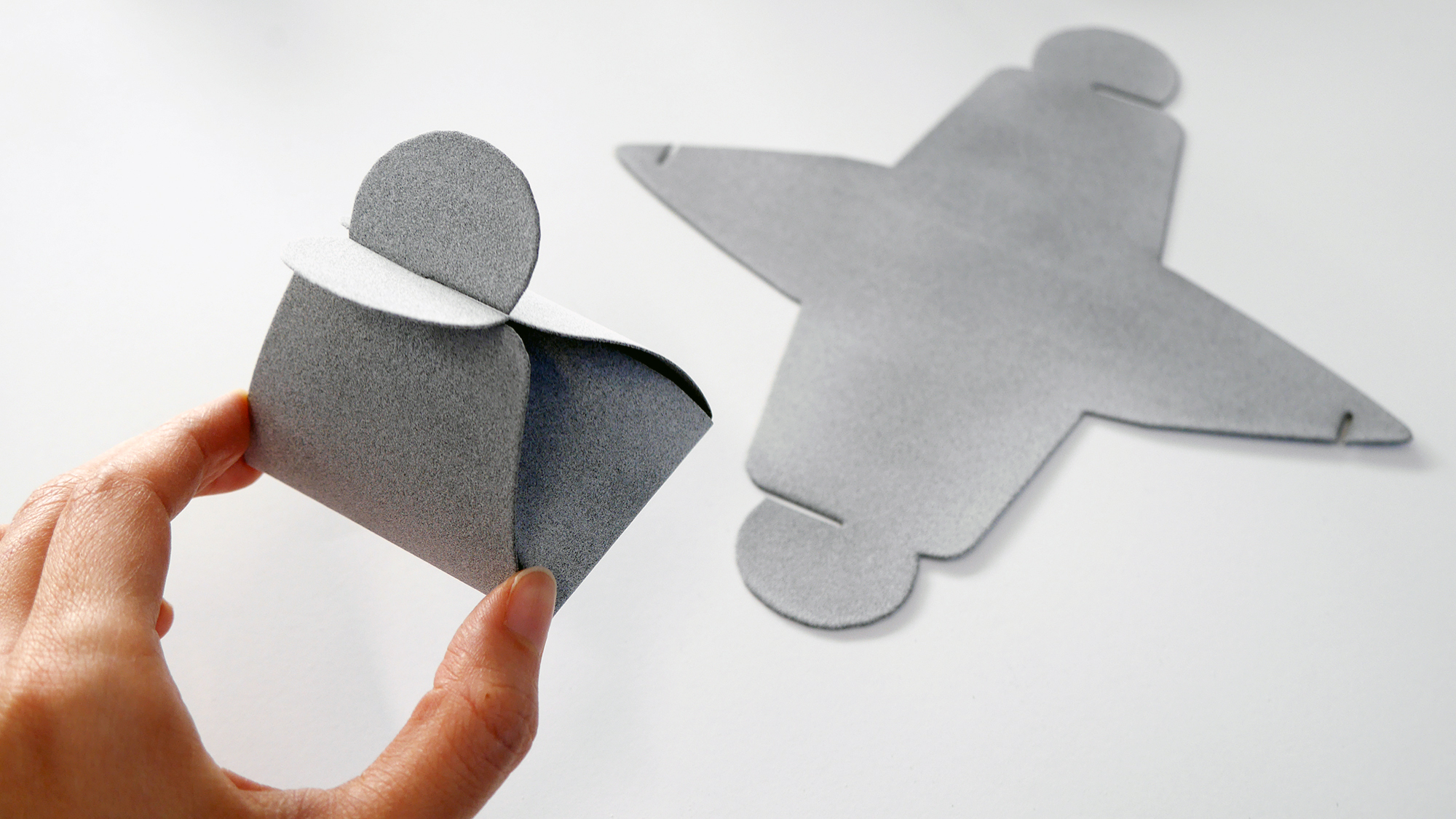

Foldable package (printed in PA12)

Lampshade (printed in PA12, dyed black)

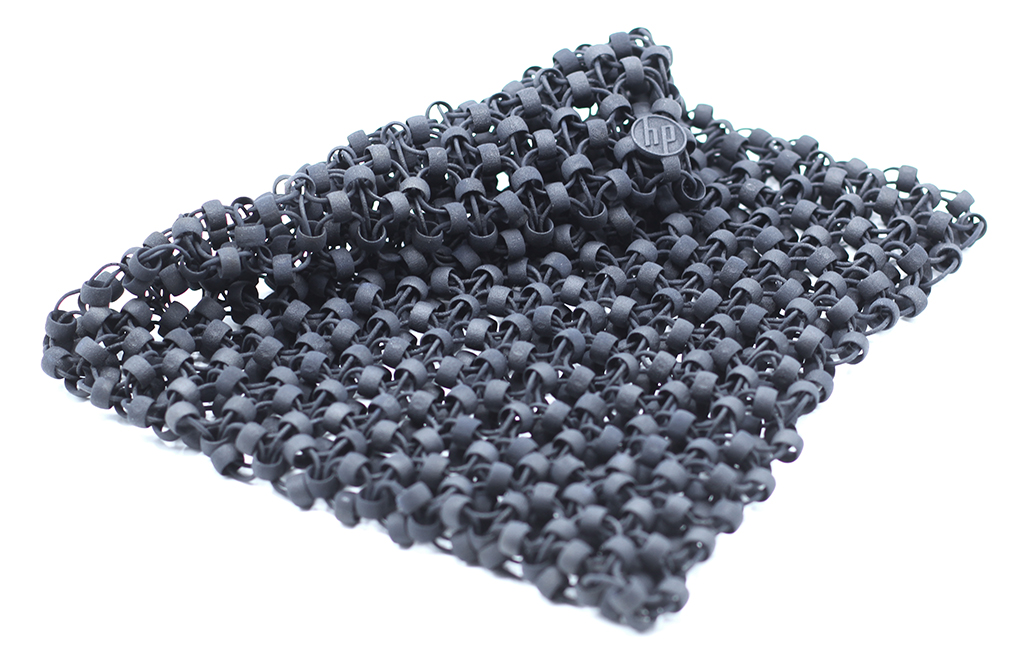

Lampshade (printed in PA12, dyed black) Interlocked fabric-like structure (printed in PA12, dyed black)

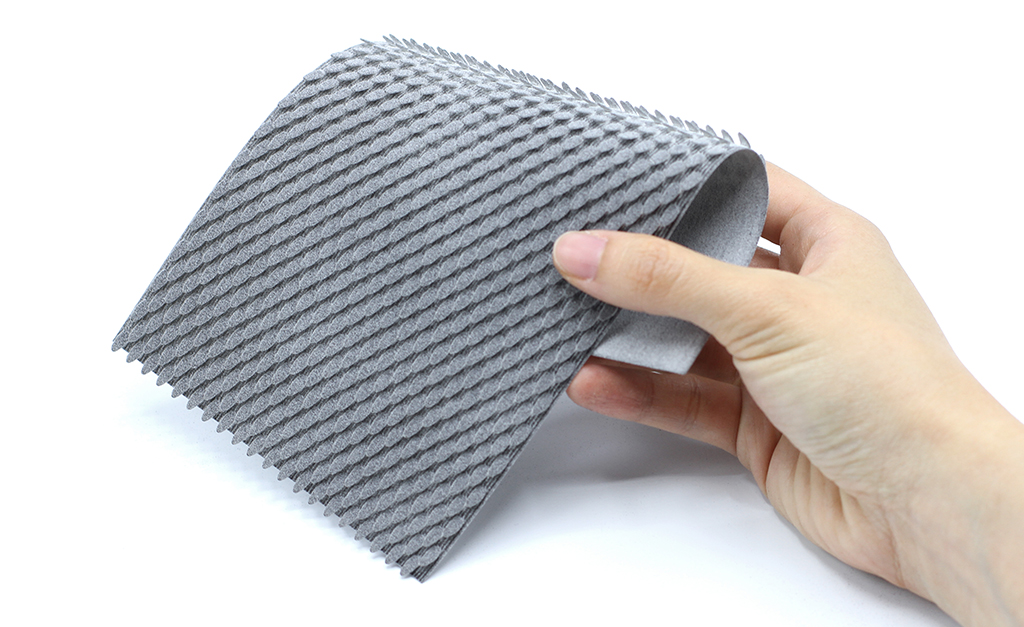

Interlocked fabric-like structure (printed in PA12, dyed black) 2.5D texture (printed in TPU)

2.5D texture (printed in TPU)

Custom designed plaque (printed in color)

2. 3D Metamaterial Structures

Company: HP Labs (2019)Team: Jiwon Jun (HP), Alexa Siu (PhD, Stanford University)

My Role: Project lead, 3D modeling

Conference: Symposium of Computational Fabrication 2019 (Demo / Abstract)

Article: Innovation Journal (Issue 11: Winter 2018) magazine

Abstract

Stretchable and reconfigurable metamaterials have recently attracted attention. These materials can be engineered to exploit motion, deformation, and mechanical energy to achieve particular physical behaviors. Although several of these concepts have been explored through simulations in idealized systems, 3D-printing the metamaterial structures is still a challenge due to its complex geometry and difficulties in achieving desired mechanical properties of the parts by controlling various factors in the printing process (e.g. material and print orientation). In this work we focus on fabricating these structures at a macro level specifically using HP’s Multi Jet Fusion (MJF) 4200 printer with Nylon PA12 material. We describe the process of translating the proposed patterns for successful realization into 3D printed parts. (Please see the full abstract here)

[Design]

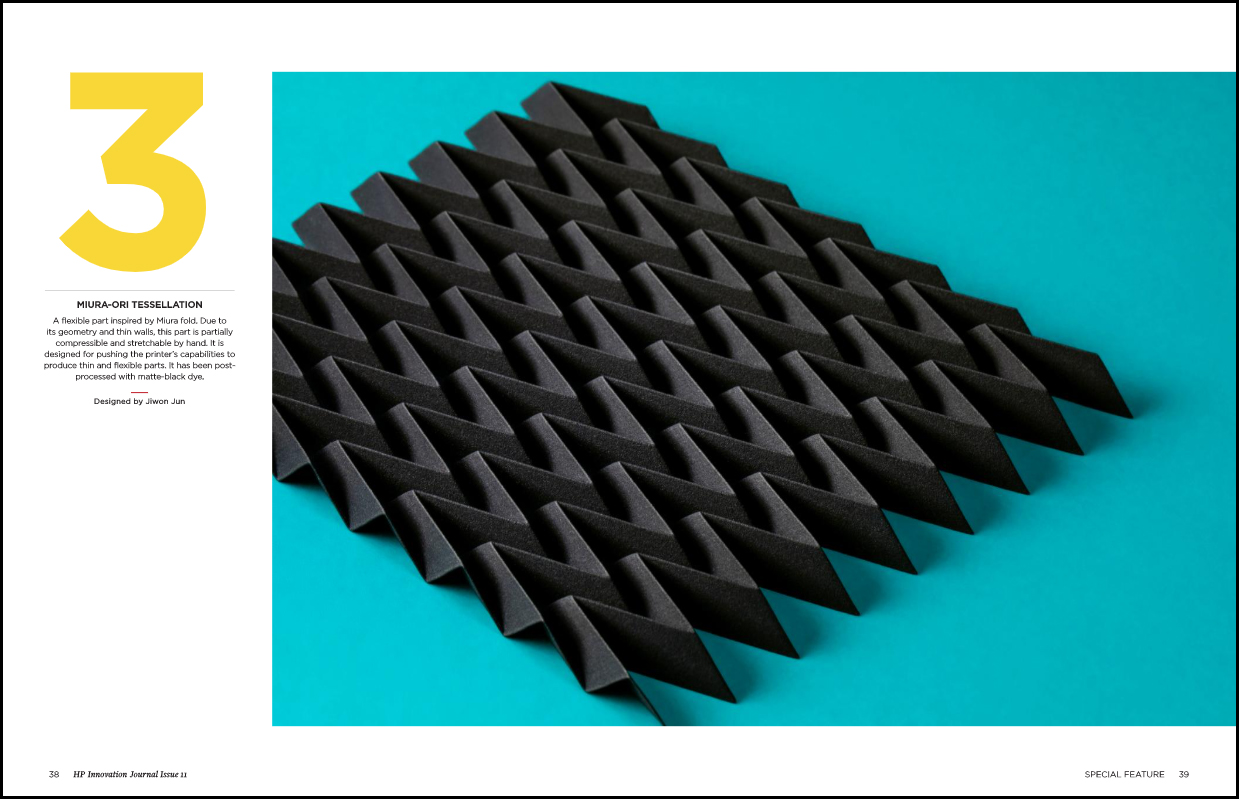

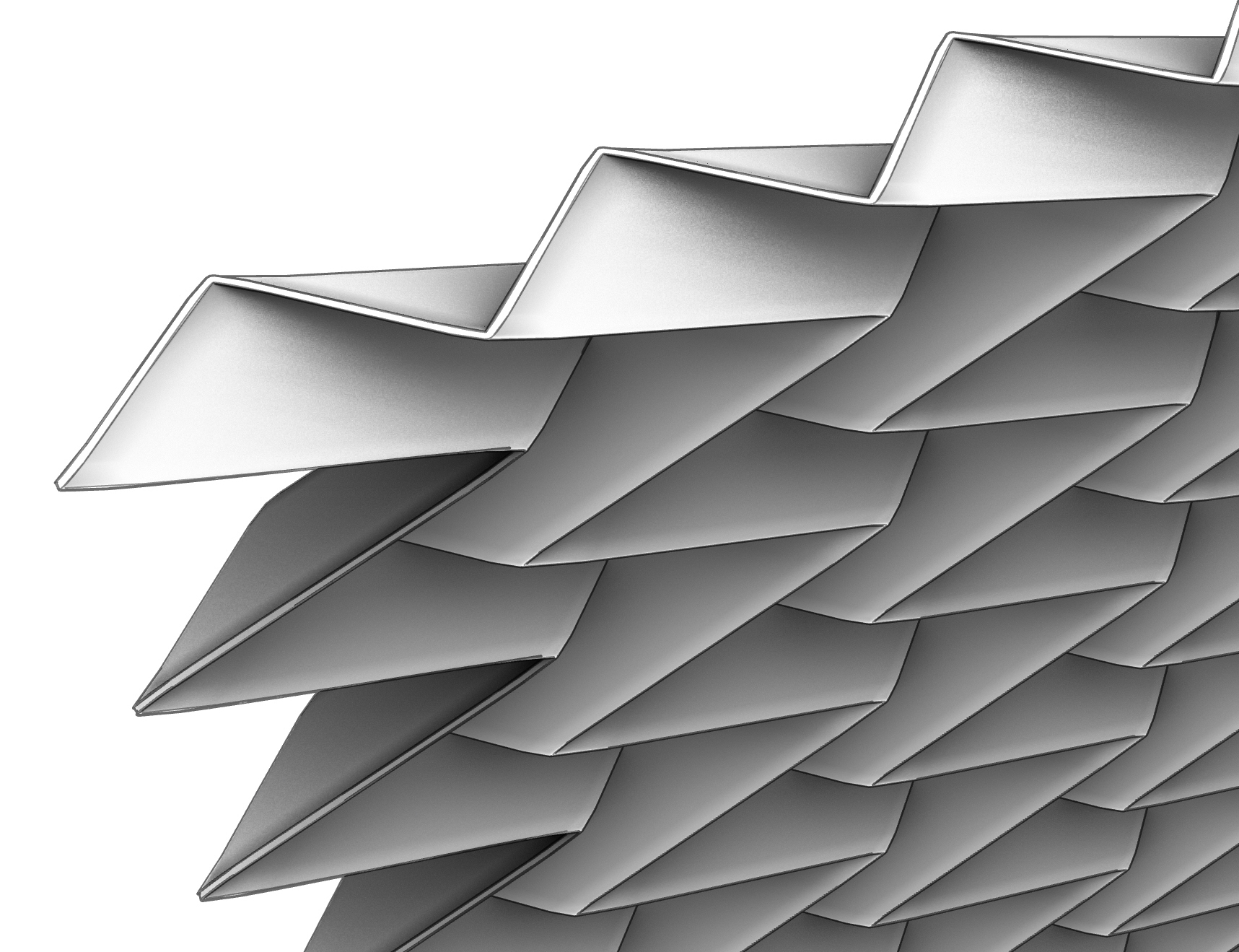

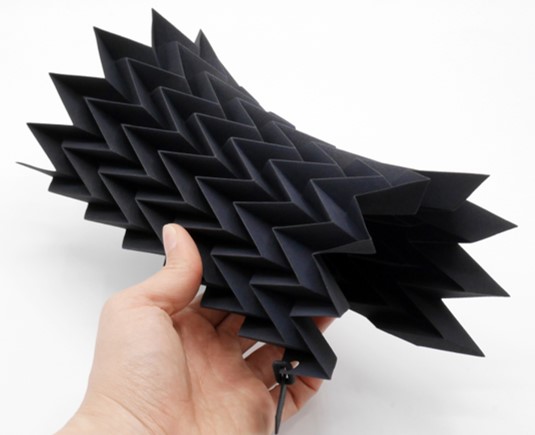

This is a flexible 3D-printed PA12 part inspired by the Miura-Ori fold. Due to its geometry and thin walls, it is partially compressible and stretchable by hand. It was demonstrated at the Symposium of Computational Fabrication 2019 as part of the project “An Exploration of 3D-Printed Metamaterial Structures” (J. W. Jun, A. F. Siu. 2019).

![]()

[Article]

Featured on Innovation Journal (Issue 11: Winter 2018) magazine.

![]()

Mirua-ori fold 3D model

The part is thinner than 1mm, and the folds function as living hinges

![]()

The part is semi-flexible and can be rolled by hand

The part is semi-flexible and can be rolled by hand

[Article]

Featured on Innovation Journal (Issue 11: Winter 2018) magazine.